The most common manufacturing methods for radiators used in combination with heat pipes or soak plates are CNC machining, forging, die casting, zipper fins, extrusion, bonding and turning.

Complex design options and high thermal conductivity are the two main advantages of CNC-machined radiators. They are expensive to manufacture and have relatively low manufacturing productivity, so they are no longer an option for cheap and/or high-volume products.

Like forged radiators, die-cast radiators have a lower unit cost and are suitable for mass production. However, for small and medium-sized batches, the early mold cost is too high. Die-cast and cold-forged radiators offer very good thermal performance. Forged radiators offer good design flexibility for complex radiators, while die-cast radiators are limited to thicker fins, making them ideal for housing covers used in natural convection applications.

Zip fin radiator

Zip-fin radiators are most popular when used with heat pipes or heat sinks, they are lightweight, offer thin, dense fins, and are easy to integrate with two-phase devices. The soaking plate can be used as the base of the fin array, while the heat pipe can pass through the center of the fin to effectively dissipate heat. Mold cost and unit price are reasonable.

Turning fin radiator

The turned fin radiator is characterized by excellent thermal performance, thin fins, high fin aspect ratio and low processing costs. However, the fins bend easily.

Bonded fin radiator

When very large radiators are needed, adhesive fins may be the answer. Another advantage is that the base can be made of a different material than the fins.

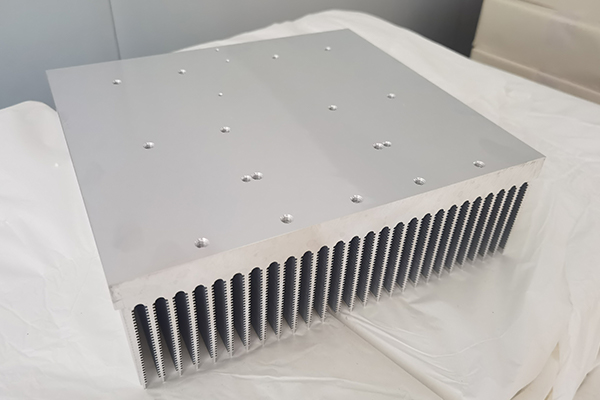

Extruded radiator

Extruded heat sinks are incredibly cost-effective, but have limited design flexibility and do not require secondary operations such as CNC machining.

Jingshengxin Technology (Shenzhen) Co., Ltd. is a custom radiator manufacturer of heat pipe technology.

We focus on: radiator design, radiator prototype, radiator manufacturing, heat pipe and other materials.