Radiators are classified according to water use

Although this category sounds unwieldy, it actually only includes solid metal radiator assemblies, radiators using two-phase devices, and pumped liquid radiators.

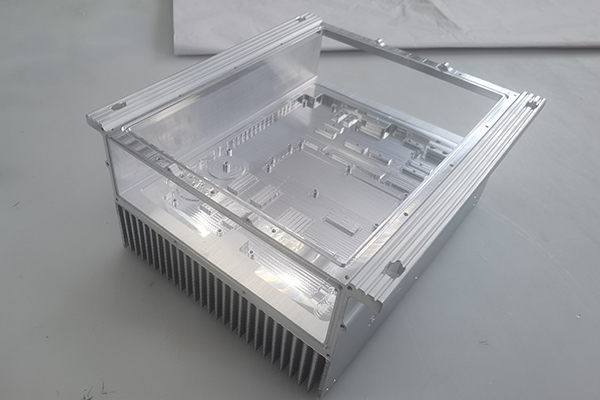

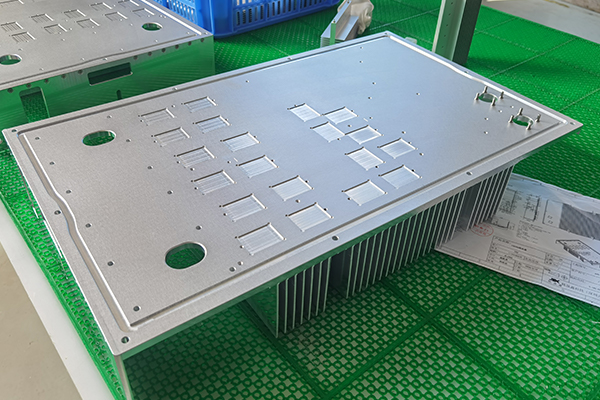

The solid metal radiator consists of a base that absorbs heat and an array of heat sinks from which heat is dissipated into the surrounding air. Depending on the manufacturing process of the radiator, the base and fins can be made of different metals - copper or aluminum for electronic cooling. Usually, these are the least expensive types of radiators.

Radiators that use pumping liquids usually refer to configurations where the pump and fin array are kept away from heat sources. The liquid is pumped into a cold plate connected to a heat source. It then returns to the fin array for cooling. Although very effective for heat dissipation, it is the least reliable method for cooling electronic devices.

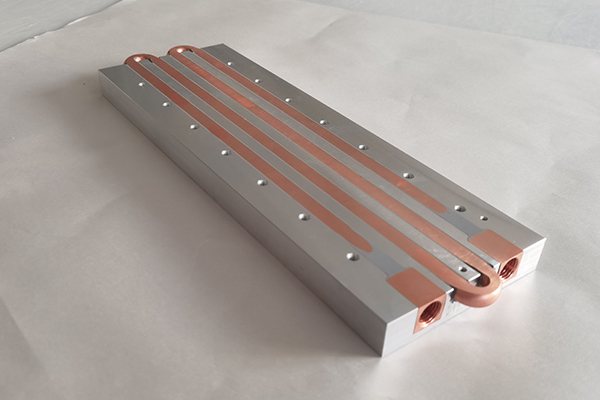

Two-phase radiator

Soaking plates and heat pipes are the most common two-phase devices that can be incorporated into a radiator assembly to improve performance. Due to the very high thermal conductivity of these two-phase devices, the overall performance of the radiator assembly is improved. Typically, heat pipes transfer heat from the heat source to the remote fin array, while a heat sink plate is used to propagate heat to the bottom of the local fin array. These types of radiators are almost as reliable as solid metal radiators, but cost slightly more.