Thermal conductivity - The thermal conductivity of heat pipes actually varies between 1,500 and 60,000 W/(mK), unlike solid metals, which have a thermal conductivity of about 180 W/(mK) for aluminum and about 400 W/(mK) for copper. The reason for the threefold increase from solid copper to heat pipes at the low end of the range is because steam is a very good heat transfer medium. For a heat pipe of a given diameter, the reason for variability or "effective thermal conductivity" is primarily explained by the length. Because the heat transfer efficiency of steam is very high, the temperature difference between the evaporator and the condenser end of the heat pipe (heat pipe Delta-T) is practically the same for short and long heat pipes, thus increasing the thermal conductivity of the heat pipe. Effective thermal conductivity.

Capillary action - When the evaporator part of the heat pipe is located in or above the condenser area, capillary action provides a mechanism by which the working fluid can return from the condenser to the evaporator. This phenomenon utilizes the inherent surface tension of the working fluid to continuously "reach" the dry part of the core; The process can be seen by partially placing a roll of paper towels into a bowl of water.

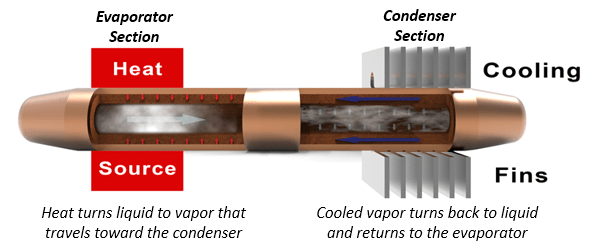

Two-pass heat cycle - When heat is applied to one end of the heat pipe, some of the liquid working fluid becomes steam and flows to the low pressure area of the cooling fin. Because the heat pipe is in a partial vacuum state, the temperature at which vaporization occurs is much lower than the boiling point at one atmosphere of pressure. At the condenser end, the steam cools and returns to liquid form, where it is absorbed by the porous core structure and transported back to the heat source by capillary action. In a steady state, the process is repeated.

Operating and non-operating temperature - the type of operating fluid determines the operating range of the heat pipe. The operating temperature of the water heat pipe is 0 oC to 200 oC. Above this temperature, the internal steam pressure increases, which may cause structural damage of the heat pipe. When the temperature is lower than the rated temperature, the heat pipe may have the phenomenon of core drying during startup. While the freeze/thaw cycle is not usually a problem for sintered core heat pipes, starting below the rated temperature can cause the frozen liquid at the evaporator end to melt and turn into steam - so far so good. However, the cold condenser area of the heat pipe causes steam to freeze at the condenser end, eventually drying out the evaporator. Although there is a risk of overheating or throttling the IC, heat pipe operation will return to normal once the ambient temperature is above freezing.